The Most Popular Methods For Creating Custom T-Shirts

Custom t-shirts have become a central element of personal expression and brand promotion. Both individuals and businesses are drawn to the flexibility of designing their own apparel, which allows them to convey messages, showcase creativity, and create group identities. These garments serve as a canvas for self-expression, making fashion more than just clothing—it becomes a statement. In business, custom shirts help develop brand awareness, while for individuals, they allow personalization that reflects personal style or interests.

With a growing interest in unique designs, the production methods behind custom t-shirts have evolved to accommodate both small, personalized orders and larger commercial needs. Understanding the popular techniques used to create custom shirts provides insight into how these garments maintain their quality, appearance, and longevity, regardless of design complexity.

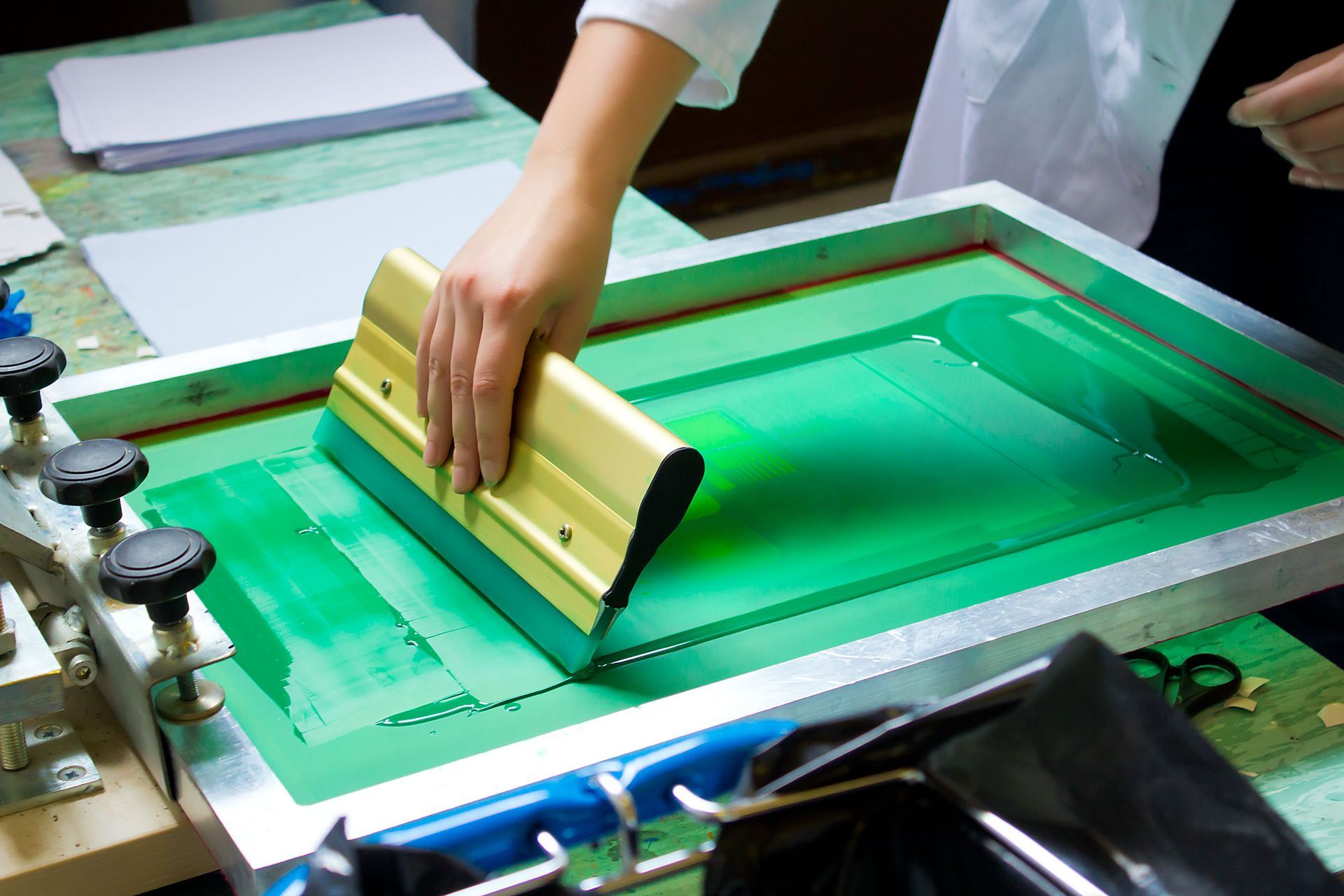

Create Durable Prints With Screen Printing

Screen printing, also known as silk screening, is a traditional method for transferring designs onto t-shirts. This technique uses a fine mesh screen to guide ink onto the fabric, producing vivid and long-lasting designs. It has remained one of the most widely used methods for custom t-shirts due to its ability to handle large orders and maintain consistent print quality. According to Printful, screen printing holds a 56% market share in the shirt printing industry, emphasizing its continued popularity.

The materials necessary for screen printing include a mesh screen, squeegee, stencil, and high-quality ink. The stencil and screen work together to control where the ink is applied, while emulsion and light exposure finalize the design template. These tools ensure that prints are sharp and colors remain vibrant over time.

The process begins by transferring the design onto an emulsion-coated screen. Light exposure hardens the emulsion in areas not covered by the design, leaving open spaces for the ink to pass through. Ink is then applied using a squeegee, embedding the design onto the fabric. The final step is heat curing, which permanently sets the ink into the fibers, resulting in durable, long-lasting prints.

Screen printing offers significant advantages, especially for larger batches. Multiple layers of ink can create rich, bold colors, and the process works well across a variety of fabric types. While the setup can be time-consuming and requires a separate screen for each color, the results are resilient and suitable for garments that are washed frequently. The raised texture of the ink can add a tactile dimension to designs, and while environmental considerations exist due to ink chemicals, the method remains highly reliable and widely used.

Apply Heat-Applied Graphics for Versatile Designs

Heat-applied graphics encompass several techniques, including transfers and embroidered patches, which are applied to garments using heat and pressure. These methods allow for detailed designs and flexibility across different fabrics, making them a popular choice for custom t-shirts. Heat-applied graphics are particularly well-suited for smaller orders or personalized items, where quick changes or adjustments to the design may be necessary.

The tools required for heat-applied graphics include a heat press and the transfer materials themselves, which could be heat transfer paper, vinyl, or pre-made patches. The process typically involves printing or cutting the design on the transfer material, positioning it on the t-shirt, and applying controlled heat and pressure. The heat activates the adhesive, ensuring the design bonds securely with the fabric fibers.

This method offers several advantages for custom shirts. Designs can include complex images, text, and patterns with sharp edges, and the application process allows for precise placement on the garment. Heat-applied graphics can also accommodate multiple colors without requiring separate screens or extensive setup. These techniques maintain consistent quality, even when applied to a variety of garment styles and materials.

While versatile, heat-applied graphics have some limitations. The resulting print may have a slightly raised or textured feel, and over time, designs can wear if not properly cared for. Certain transfer materials may not perform as well on very dark fabrics or highly textured surfaces. Despite these considerations, heat-applied graphics remain a widely used method for producing visually striking and personalized custom t-shirts.

Combine Techniques With Embroidery for Added Texture

Embroidery is another heat-related method that enhances custom shirts by adding textured designs with thread. Unlike ink-based methods, embroidery creates raised patterns and logos directly on the fabric, providing a durable and professional look. This technique works well for corporate apparel, uniforms, and fashion-forward designs that benefit from tactile details.

Embroidery involves digitizing a design into a format readable by an embroidery machine. The machine then stitches the design using colored threads onto the garment, often following precise paths to achieve logos, lettering, or intricate patterns. The process requires quality threads, stabilizers, and accurate placement to ensure consistency across multiple garments.

One of the main advantages of embroidery is its durability. Thread designs can withstand repeated washes without significant fading or distortion. The raised texture adds a dimensional quality to custom t-shirts, giving designs a premium feel. However, embroidery is generally better suited for simpler designs and may not be ideal for highly detailed or photographic images. While it involves a higher initial setup for complex logos, the result is long-lasting and visually appealing.

Embroidery, often combined with heat-applied techniques like patches or transfers, provides additional creative possibilities for custom shirts. By layering embroidered elements with printed designs, creators can produce garments that stand out both visually and texturally. The versatility of these methods allows for a wide range of applications, from casual wear to professional uniforms.

Maintain Quality With Proper Material Selection

An important consideration for all custom t-shirt methods is the choice of fabric. Materials like cotton, polyester blends, or performance fabrics can affect how ink, transfers, or embroidery adhere to the garment. Cotton is highly absorbent, making it suitable for screen printing and heat-applied graphics, while polyester blends work well with thread-based designs and transfers that require smooth surfaces. Understanding fabric properties ensures that designs remain vibrant, durable, and comfortable for wearers.

The weight, texture, and weave of a fabric influence the final appearance of the design. Heavier fabrics provide a stable surface for embroidery, preventing distortion, while lighter fabrics allow for smooth transfers with minimal ink buildup. Considering these factors during the planning phase ensures that custom shirts maintain professional-quality results across multiple printing or application methods.

Achieve Consistent Results Across Orders

Consistency is key when producing custom t-shirts, whether for individual gifts or large-scale orders. Screen printing and heat-applied graphics allow for reliable replication of colors, placement, and detail across multiple garments. Using high-quality inks, threads, and transfer materials, along with proper temperature and pressure settings, helps maintain uniformity. This reliability makes these methods suitable for businesses producing branded apparel as well as individuals seeking uniform designs for events or personal projects.

By following structured processes and monitoring quality throughout production, it is possible to achieve both visually appealing and long-lasting results. Techniques like screen printing and embroidery have a proven track record for durability and precision, ensuring that each custom t-shirt maintains the intended look and feel.

The world of custom shirts relies on versatile methods that balance durability, detail, and design flexibility. Screen printing continues to dominate for its bright, long-lasting prints, while heat-applied graphics and embroidery provide opportunities for creative expression and texture. Each approach offers unique benefits, depending on the complexity of the design, the order size, and the type of fabric used. Understanding these methods helps anyone interested in creating custom t-shirts select the most appropriate approach for their project.

For professional-quality results, contact us at Embroidery Creations of Londonderry. We will bring your designs to life with precision and consistency.

Share On: